Our Process

The Consult

Our engineering team meets with you to understand your production goals, spatial constraints, and technical requirements. We review existing infrastructure and discuss material specifications, pressure ratings, and compliance needs.

Whether you're expanding capacity or solving a specific operational challenge, we translate your vision into actionable specifications.

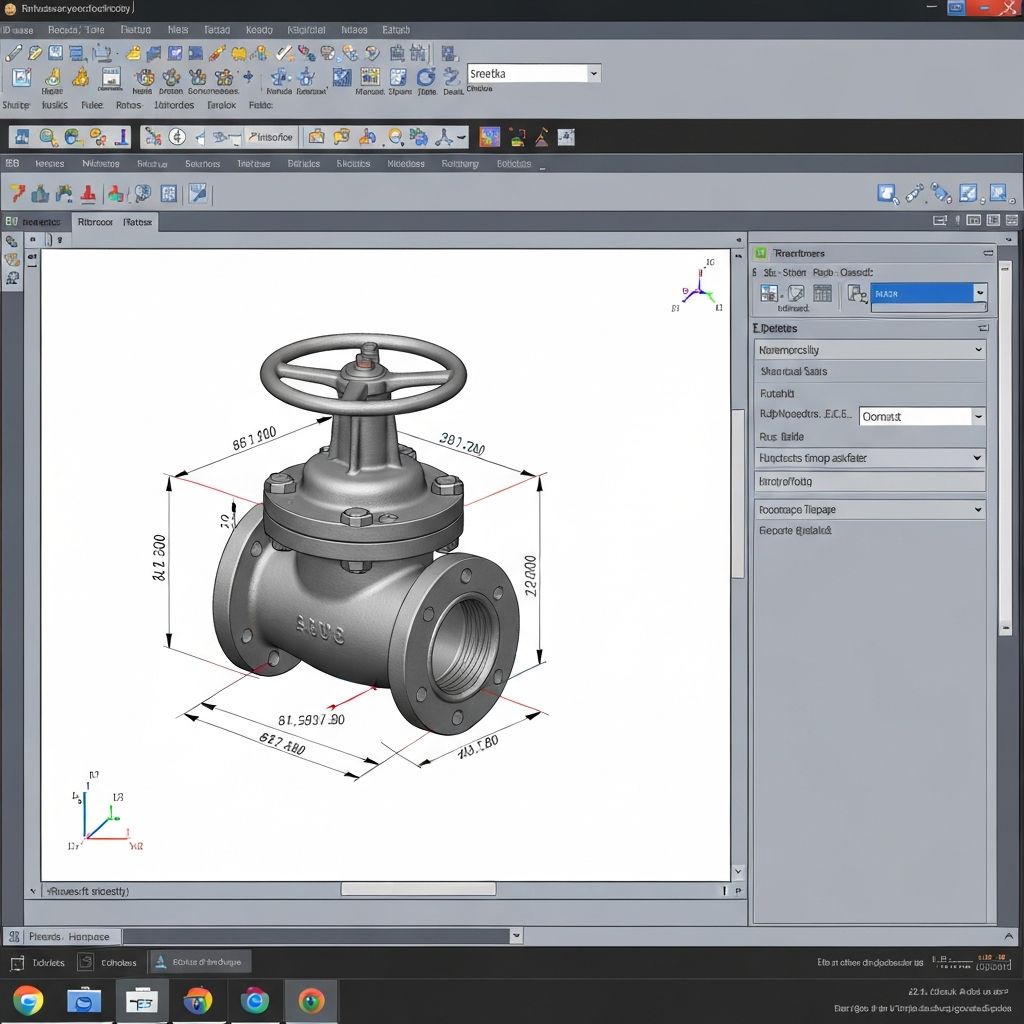

CAD Design

We create detailed 3D models and technical drawings using industry-standard CAD software. Every dimension is verified, every stress point analyzed, and every weld location documented.

You'll receive comprehensive design files showing how your custom equipment integrates with existing systems, plus material specifications and cost breakdowns.

Fabrication

Our certified welders and machinists bring your design to life using precision CNC equipment and sanitary welding techniques. Every component is built to exact specifications using FDA-compliant 304 or 316 stainless steel.

Throughout fabrication, we conduct quality checks and document progress with detailed photography and inspection reports.

Installation & Support

Our installation team delivers, positions, and connects your custom equipment, ensuring proper alignment and leak-free operation. We pressure-test all connections and verify system integration.

After installation, we provide operator training and comprehensive documentation, plus ongoing technical support throughout the life of your equipment.

Core Capabilities

TIG Welding

Sanitary-grade stainless steel welding with full penetration and smooth interior finish

CNC Machining

Precision fabrication with tolerances to 0.001" for perfect fitment

Electropolishing

Mirror-finish surface treatment for enhanced cleanability and corrosion resistance

On-Site Installation

Professional installation services with pressure testing and system integration

Ready to Build Something Exceptional?

Let's discuss your project requirements and create a custom solution that exceeds your expectations.